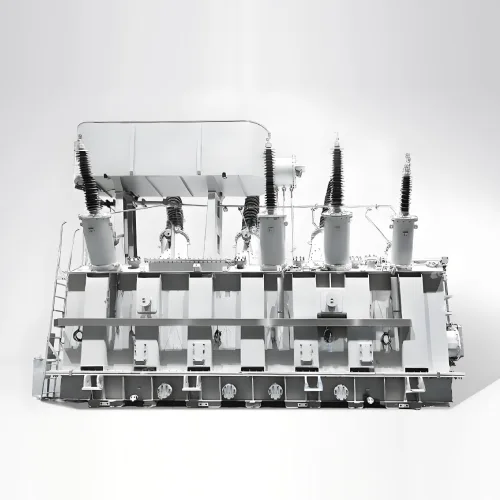

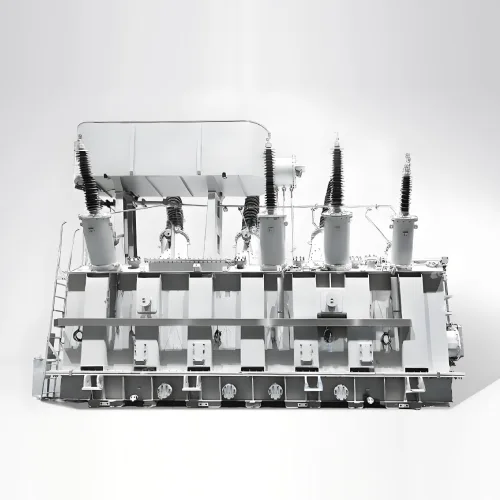

Scope of application

220kV oil-immersed transformer is very suitable for operation under high temperature conditions and can cope with high load conditions, especially suitable for the peak summer of the distribution network. It is also well suited for places that need to cope with shock loads and continuous overloads, such as steel, metallurgy, railroad transportation, power plants, hydropower stations and other industries.

Product Description

1. fully closed manufacturing: adopting fully closed manufacturing process to ensure constant temperature, constant humidity and dust-free environment, and strictly controlling product quality with lean management.

2. seven-level temperature control: equipped with “seven-level temperature control technology” system, and combined with the temperature field finite element analysis, fully optimize the performance of various types of insulating materials.

3. Noise reduction technology: According to the noise generation mechanism, exclusive noise reduction technology is adopted in different parts to ensure that the noise level is better than the national standard.

4. Seal detection: Sealed structural parts are manufactured by one-time molding technology, and fluorescence detection, positive pressure leakage test and negative pressure leakage test and other multiple testing methods are adopted to eliminate the risk of leakage.

5. Iron core technology: the iron core uses Swiss imported cross-cutting, stacking and loading integrated automatic robot production line, which significantly reduces the no-load loss by 20% compared with the traditional process.

6. Safety and reliability: the product has passed the sudden short circuit test of the National Transformer Testing Center, which is qualified at one time to ensure safety and reliability.

Product features

Low loss performance

The product's no-load loss is more than 10% lower than the current national standard, and the load loss is more than 5% lower than the current national standard, and the overall performance reaches and conforms to the energy-efficiency standard.

Low noise design

Noise level under self-cooling state is controlled below 60dB, and customized ultra-low noise transformer solutions are available for users with special needs.

High heat dissipation performance

The use of high-quality insulating oil and advanced heat dissipation structure design, effectively reduce the operating temperature of the transformer, prolong the service life.

High reliability

With strong short-circuit resistance and environmental resistance, it is able to operate stably in complex power grids.

Main Parameters

Rated capacity: 50kVA to 1000MVA

Rated voltage: 6kV~500kV on high voltage side, 0.4kV on low voltage side

Rated frequency: 50Hz or 60Hz

Connection group: commonly Dyn11, Yyn0, Yd11

Insulation class: usually A or F class

Implementation standard

GB 1094 Power Transformer

GB/T 6451 Oil-immersed power transformer technical parameters and requirements

GB/T 10228 Power transformer technical parameters and requirements

IEC 60354 Load guidelines for transformers

ISO 14001 Environmental Management System Specification

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.