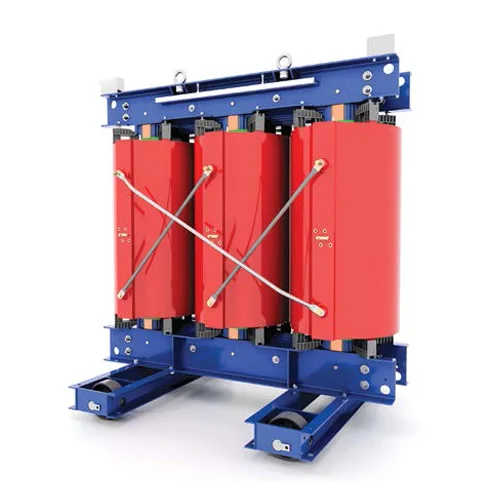

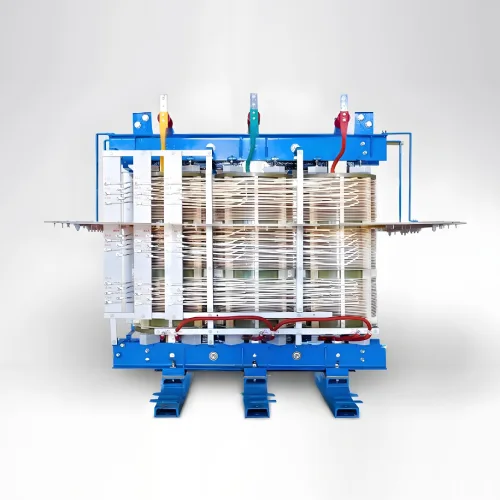

The 400 kVA Dry Transformer is designed for the modernization of the 6.3 kV and 20 kV CHE Scropoasa substation. This high-performance, three-phase transformer operates without protective casing and features a durable, maintenance-free construction, ideal for supplying 0.4 kV AC services in a 50 Hz environment.

Key Specifications:

Power Rating: 400 kVA

Voltages:

6.3 kV Model: Primary 6.3 kV / Secondary 0.4 kV

20 kV Model: Primary 20 kV / Secondary 0.4 kV

Cooling System: Natural air circulation

Temperature Class:According to SR EN 60076-3

Maximum Winding Overtemperature: 100°C

Noise Intensity: 63 dB

Insulation: Epoxy resin and quartz powder blend for maintenance-free operation, moisture resistance, and fire safety.

Core: Low-loss cold-rolled silicon steel with high magnetic permeability and low hysteresis and eddy current losses.

Windings: Copper with epoxy resin insulation; high mechanical strength against short-circuit forces.

Technical Features:

Connection: Dyn-5

Adjustment: 5-step voltage adjustment with ±2x2.5% range on the high voltage side, performed in the absence of voltage.

Insulation Level: F

Environmental Conditions:

Maximum Ambient Temperature: +40°C

Minimum Ambient Temperature: -30°C

Altitude: <1200 meters

Humidity: <100% at 20°C

Seismicity: 760±15 mmHg

Accessories:

Trolley: With bidirectional wheels and a wheel locking device

Temperature Sensors: At least 3 PT100

Temperature Control Unit: Integrated into the protection, signaling, and monitoring system

Lifting Lugs: For easy handling

Neutral Terminal: Accessible on the low voltage side for the 400 kVA, 6.3/0.4 kV transformer

Compliance:

Standards: EN 60076. CEI 60076 series, IEC 60185. DIN-VDE 0414-1

ECO Design Directive: Compliant with 548/2014 and subsequent amendments

Operational Flexibility:

Overload Capability:

10% overload for 1 hour

20% overload for 30 minutes

30% overload for 15 minutes

40% overload for 8 minutes

50% overload for 4 minutes

Overexcitation Tolerance: Capable of operating with a 5% maximum deviation from nominal voltage and frequency.

Testing

All transformers undergo rigorous factory testing, including:

Verification of transformation ratio

Connection group checking

Winding resistance measurement

Insulation resistance and absorption coefficient testing

Dielectric loss angle tangent measurement

Applied voltage and induced voltage tests

Measurement of no-load and short-circuit losses

Winding overheating and homopolar impedance measurement

Noise level assessment

Dielectric rigidity of the oil

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.