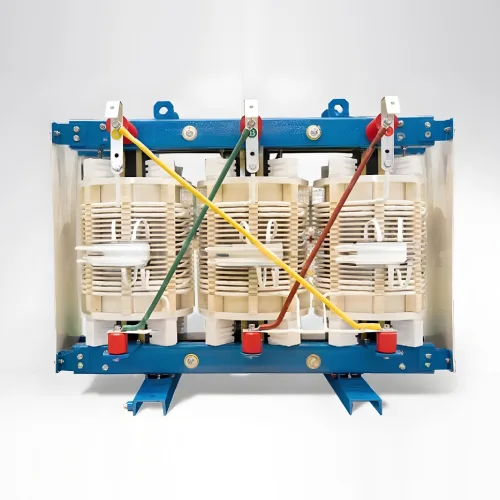

Auto Transformers have the capability to supply a varying secondary voltage to an externally connected load. This is used predominantly is applications where various voltage outputs are required such as:

- Electronics testing centers where continuously varying voltage supplies are required

- Applications such as power stations which initially require a step up/step down followed by an increase/decrease to match the voltage required by the device at the receiving end

- Motor starting applications

Key 2025 Specifications:

Voltage Range: 110V–33kV (adjustable ±10% via 5-tap selector)

Capacity: 1kVA–10MVA, achieving 99.1% efficiency at 75% load (DOE Tier 3)

Insulation: Class F (155°C) with flame-retardant silicone coatings (UL 506-2025 certified)

Core Material: Laser-etched amorphous steel strips (15% lighter, 20% lower no-load loss)

Smart Features: Embedded IoT sensors for real-time harmonics analysis (±2% THD monitoring) and predictive fault alerts via LoRaWAN connectivity.

Recent deployments, such as Tesla’s Nevada Gigafactory upgrade, leverage autotransformers with hydrogen-cooled windings (reducing thermal stress by 40%) and modular designs compliant with NEC 2025 Article 450.4(B) for rapid grid integration. Eco-focused variants now use 95% recycled copper and blockchain-tracked supply chains to meet EU Ecodesign 2025/178 sustainability mandates.

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.