Scope of application

Suitable for use with high voltage inverter, mainly in municipal water supply, electric power, metallurgy, petroleum, petrochemical, cement, coal and other industries.

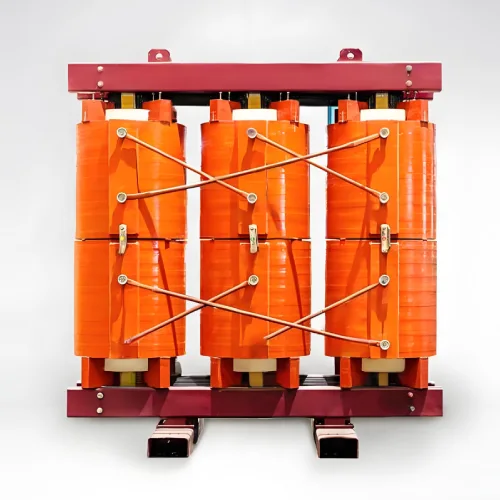

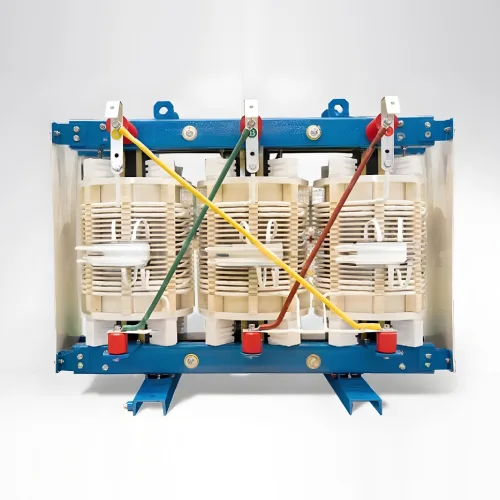

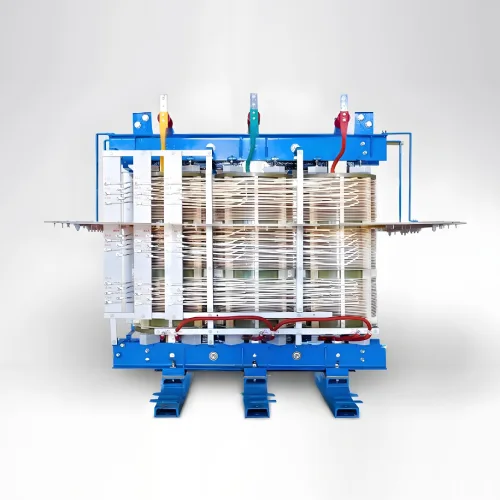

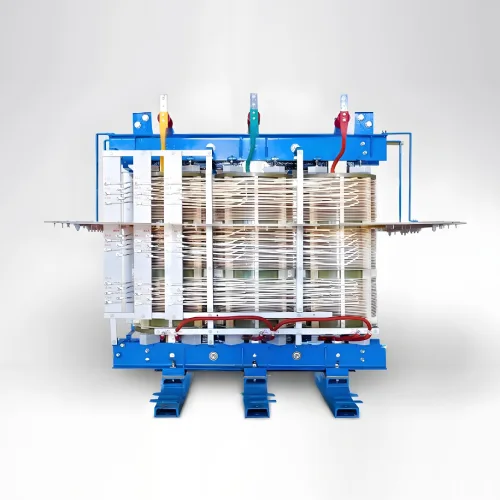

Product Description

1. The iron core adopts multi-stage stepping process through the core positioning structure, under various working conditions, the iron core has no lateral and longitudinal displacement.

2. The winding adopts various structural types, with strong short-circuit resistance.

3. Adopting special air-cooling guide system, high heat dissipation efficiency, safe and reliable products.

4. Reasonable magnetic leakage distribution, fully meet the requirements of inverter sinking.

5. Adopting multiplication technology, effectively suppressing harmonic content, realizing perfect harmonic-free, and prolonging the life of the motor.

6. Various structure types can meet the requirements of various frequency conversion systems.

7. The highest capacity of the product can reach 9000kVA, and it can realize 72 pulse wave rectification.

Product features

High efficiency and energy saving

Adopting advanced design, low running noise, power saving efficiency up to 40%, significantly reducing energy consumption.

High-quality core material

The core is made of high-quality cold-rolled silicon steel sheet with 45° full-slope stacking process to ensure low loss and high performance.

Optimized wiring technology

The secondary side adopts the extended triangle connection method, which effectively reduces the input current harmonics and improves the power quality.

Structural innovation

Layered structure: phase-shifted leads on the secondary side are designed in layers to enhance product aesthetics and ease of installation. Removable and assembled: the dividing partition adopts removable and assembled structure, which is convenient for installation, maintenance and transportation.

Excellent operational performance

Strong short-circuit resistance: high mechanical strength, able to withstand high current impact, safer and more reliable operation.

Safe and reliable

Excellent flame retardant characteristics ensure safety and reliability in various environments.

Main Parameters

Ambient temperature: -10°C~40°C

Relative humidity: ≤95%.

Altitude: ≤1000 meters

Pollution level: Ⅲ

Frequency: 50Hz or 60Hz

Cooling: Natural air-cooled (AN) or forced air-cooled (AF)

Service life: 20 years

Execution standard

GB/T 10228-2015 Technical parameters and requirements applicable to dry-type power transformers

GB 1094.11-2007 specifies the test methods and technical requirements for dry-type transformers.

GB/T 22072-2008 Technical conditions for transformers for frequency conversion and speed regulation

JB/T 10088-2004 covers the technical requirements for dry-type power transformers of 6kV class and above.

IEC 60076-11:2004 International Electrotechnical Commission standard for dry-type transformers

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.