Scope of Application

Variable current rectifier is widely used in the fields of electrochemistry, electric power, hydrogen energy and renewable energy. It is mainly used in the process of electrolysis of aluminum, copper and other metals, electrolysis of water to produce hydrogen, chlor-alkali production, etc. It is also suitable for the conversion of electric energy in photovoltaic and wind power generation systems. In addition, it can also provide stable DC power supply for heavy industries such as steel and fertilizer, and support the efficient operation of environmental protection projects. Through the rectifier, it can improve energy utilization efficiency and promote green and low-carbon energy transformation.

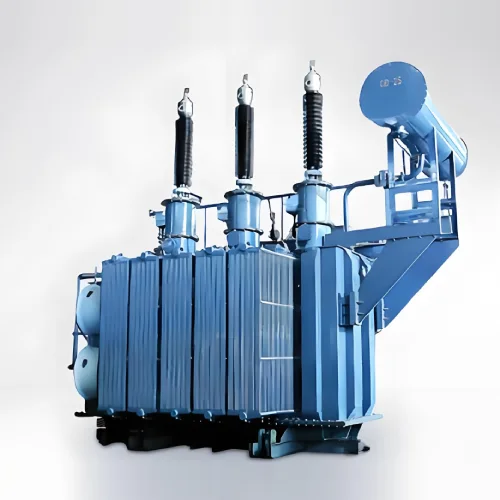

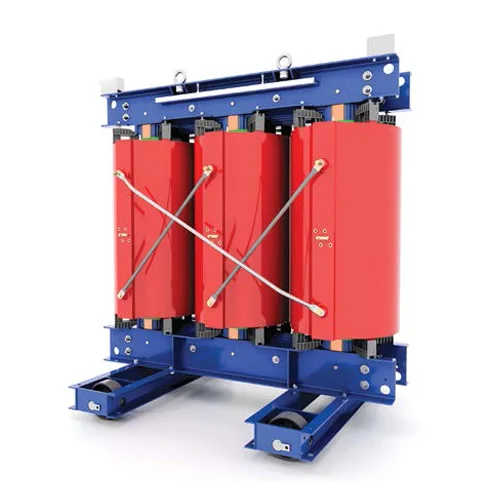

Product Description

Rectifier function: Rectifier equipment can convert AC power to DC power to ensure efficient and stable operation of electrolysis, chemical reaction and other processes, which is an indispensable core component in industrial electrochemical applications.

Electrochemical industry applications: Widely used in the production of electrolysis of non-ferrous metals (such as aluminum, copper, magnesium, etc.), chlor-alkali chemical production, electrolysis of water to produce hydrogen and other key processes, to meet the requirements of high efficiency and stability in different fields.

Hydrogen production: High purity hydrogen and oxygen are produced by combining renewable energy sources (e.g. photovoltaic and wind energy) with rectifier equipment and water electrolysis technology, providing technical support for the global hydrogen industry and helping the green and low-carbon energy transition.

Environmental protection and energy saving: The use of high-efficiency rectifier equipment reduces energy loss and improves the overall energy efficiency of the system, which is in line with the global green development trend and contributes to carbon neutrality and sustainable development goals.

Strong applicability: Applicable to a variety of industrial scenarios, especially in the fields of electrochemistry, electric power, hydrogen energy and other fields with a wide range of application prospects, able to support large-scale, continuous and stable production processes.

Product Features

Safe and Reliable

Adopting non-toxic, flame-retardant epoxy resin infusion process, it has high mechanical strength, is flame retardant, fireproof and non-polluting, which ensures the safety of use.

Convenient installation

The whole machine can be put into operation directly after arrival, simple and efficient installation, reducing construction time and complexity.

High overload capacity

Transformer insulation heat-resistant grade H, temperature resistance up to 180 ℃, and has a maximum overload capacity of 200%, to ensure stable operation under high load.

Low noise

The noise level is 3~5 dB lower than the national standard, effectively reducing the interference to the surrounding environment and enhancing the comfort of use.

Investment Saving

Can be integrated with rectifier and other equipment, eliminating the need to design a separate distribution room, saving space and initial investment costs.

Main Parameters

Rated capacity: kVA or MVA

Rated voltage: input and output voltage

Overload capacity: usually 200% of rated capacity

Losses: No-load and load losses

Operating temperature range: -5°C to 40°C

Implementation standards

GB/T 10228 Dry-type transformer

IEC 60076 Power Transformer

GB/T 6451 Seismic design code for electrical equipment

GB/T 11022 Low-voltage power distribution and control equipment

IEC 60726 Testing of dry-type power transformers

Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.